One way to improve capacity utilization of trailers and carriers in transportation is via Collaborative Shipping — for example, where one or more shippers co-load freight on a trailer or where freight lanes are matched to create reliable and consistent continuous move routes.

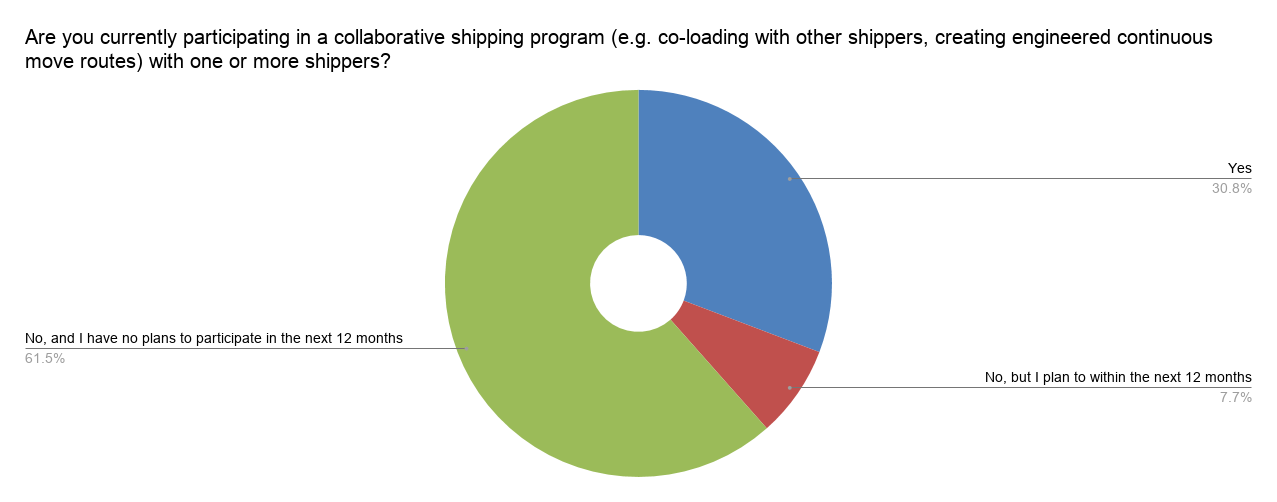

Are you currently participating in a collaborative shipping program (e.g. co-loading with other shippers, creating engineered continuous move routes) with one or more shippers?

We asked our Indago members that question back in January. Only about a third of our member respondents (31%) were participating in a collaborative shipping program, with an additional 8% planning to do so this year.

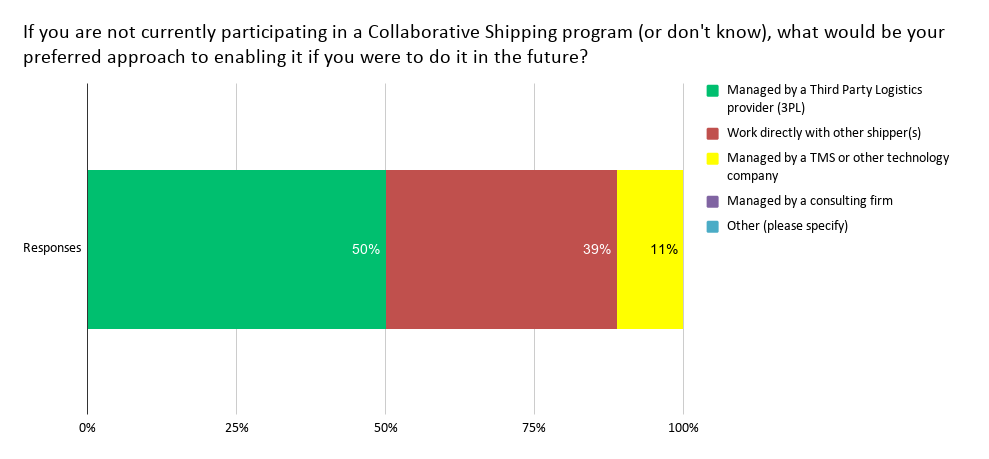

Of those participating in a collaborative shipping program, the majority (63%) were being managed by third-party logistics providers, while none were working directly with other shippers. In contrast, 39% of those who were not participating in a collaborative shipping program said that “working directly with other shippers” would be their preferred choice.

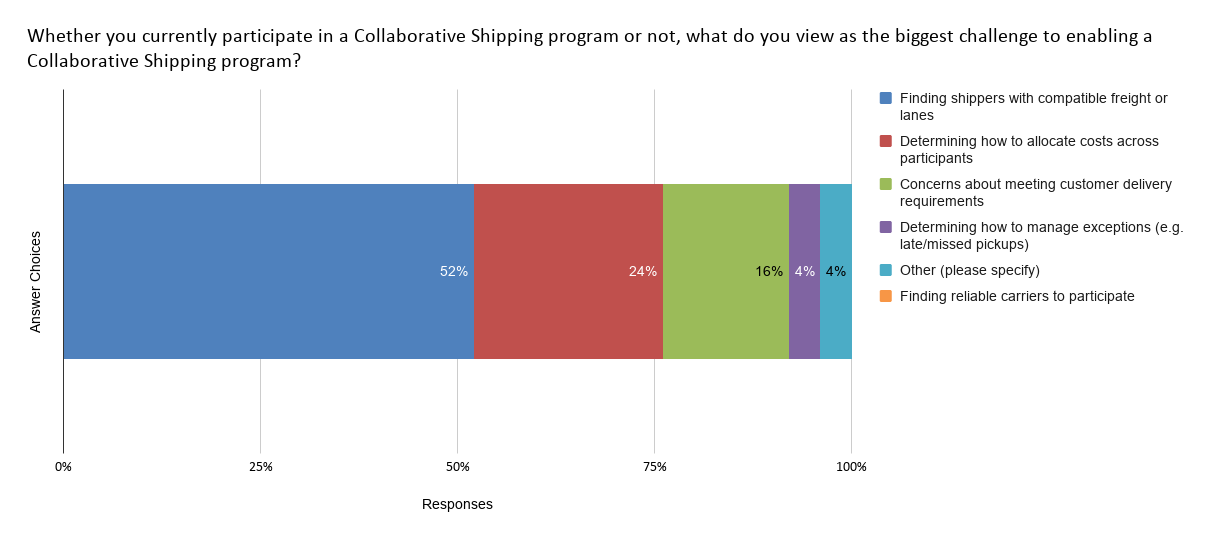

More than half of the member respondents (52%) said that “finding shippers with compatible freight or lanes” is the biggest challenge in enabling a collaborative shipping program, followed by “determining how to allocate costs across participants” (24%).

Here are some value-added comments from our Indago members, who are all supply chain and logistics professionals from manufacturing, retail, and distribution companies:

“Our dedicated provider has brought opportunities to us on lanes where we have matching volume. They then coordinate the logistics.”

“We ship inbound collaboratively, but it is across two business units (owned by the same parent) that share suppliers. We operate JIT on the outbound side, so if we shared capacity the other party would need to have less time sensitivity. We haven’t looked at it too much because we take orders until the last minute and it would require a system that better predicted how much capacity our load will take [in a trailer] far enough in advance for the other party to plan.”

“We are very interested in this arena. With a private fleet running at approximately 45% empty, collaborative shipping is a way that we are improving utilization and offsetting costs.”

“I have [done collaborative shipping in] the past. One issue we had was with data integrity; not all shippers understand cube. We would plan for X skids and the driver would show up with less than that available [in the truck]. I think using a 3PL to manage [the process] would help, as we did this with another shipper directly.”

“Collaborative shipping would be a great way to reduce emissions and overall carbon footprints, but it would rely on finding a symbiotic partner, which is a relatively difficult thing to find.”

“We have used a 3rd party to accomplish this for certain customers. We have tried to partner with other suppliers and had issues coordinating the execution between our operations and managing the allocation of cost.”

“Sharing trailer space helps promote more sustainable shipping practices. The trickiest part is coordinating timing with the carrier (i.e., delivery appointments, loading sequences, etc.)”

What is your experience with collaborative shipping? Is there greater impetus to do it today than in the past? What is the most critical factor for success? Post a comment and share your perspective!

For related commentary, please read Freight Lane Matching And Collaboration.

Join Indago

Also, If you’re a supply chain or logistics practitioner from a manufacturing, retail, or distribution company, I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-5 minutes per week) — plus your participation will help support charitable causes like JDRF, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.

You can also follow us on LinkedIn to stay informed of our latest research results and news.