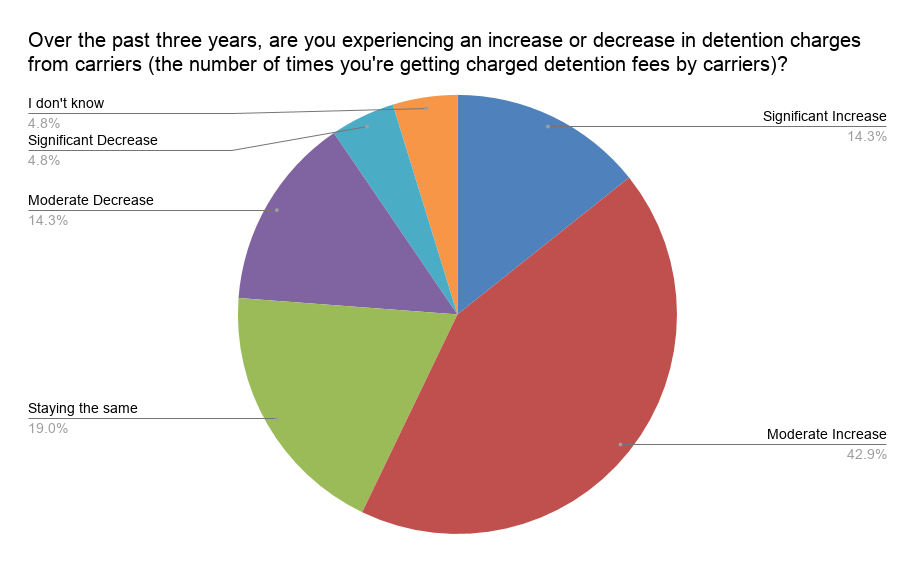

Over the past three years, are you experiencing an increase or decrease in detention charges from carriers (the number of times you’re getting charged detention fees by carriers)?

We asked our Indago research community that question back in September. More than half of our member respondents (57%) have experienced a moderate to significant increase over the past three years in the number of times they are getting charged detention fees by carriers. 19% said the rate of charges has remained the same, while another 19% have experienced a moderate to significant decrease.

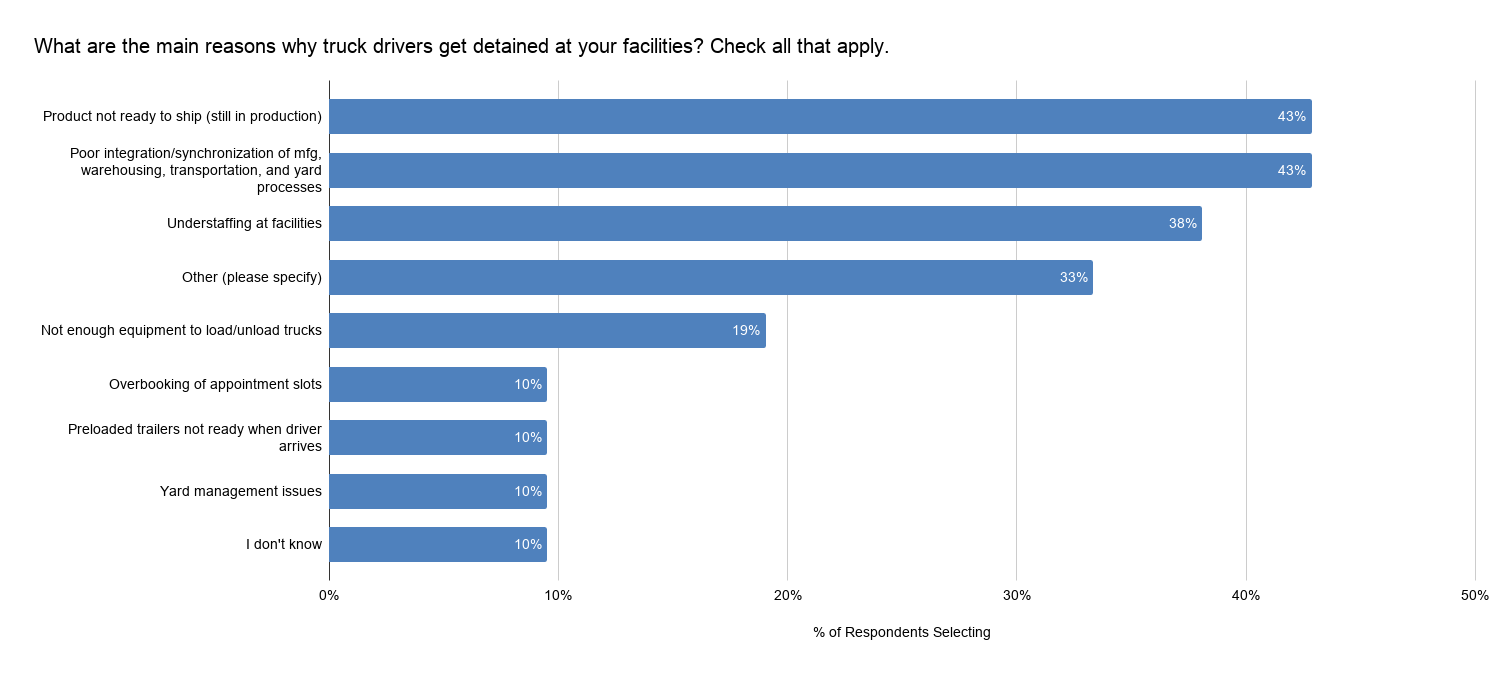

There are many reasons why truck drivers get detained at facilities, but the top three cited by the respondents are product not being ready to ship (43%), poor integration/synchronization of processes (43%), and understaffing at facilities (38%).

Here are some value-added comments from our Indago members, who are all supply chain and logistics professionals from manufacturing, retail, and distribution companies:

“The concept of lean manufacturing and lean inventory management is part of the problem because often times they are put in place in a vacuum without taking into consideration the other impacts it has on operations. [Another issue] is that facilities cannot accommodate the volume of business. Not enough space to stage prior to loading leads to pickings at the time of pickup. Lack of lot space means drop trailer [isn’t] an option. On the delivery side, you have receivers that really don’t care especially if they aren’t paying the bill and have an OTIF program that penalizes the shipper.”

“For us, warehouse labor is one of the biggest issues. We try to be flexible as much as possible with drivers, especially if they are on time for their appointment. If they are late, we work them in and try our best to minimize delays. If they are early and we are not busy, we will load them and get them on the road.”

“The majority of time I believe it is a staffing/planning opportunity. Many schedulers plan for perfect in order to get all needed items into the flow. Productivity standards are key, but things happen, planning for perfect will snowball and the amount of detention fees will increase. I have found that taking a step back and understanding the planned schedule will help, just a reality check. It is always tough to be the reviewer and doer, we as leaders need to help our teams and become the reviewer/coach.”

“We attempt to fully utilize the truckload space especially given the uncertainty of when a carrier will be able to return for the next shipment. This in turn means that distribution teams may still be picking and packing stock leading to longer wait times.”

“I am confident that this is a significant opportunity across the entire supply chain. I believe that a better understanding of the cost impact at the location level (i.e., detention, lost productivity, increased freight rates, etc.), along with improved visibility tools and improved scheduling/yard management tools can significantly reduce detention and demurrage.”

Do you agree with the feedback and advice of our Indago members? Anything you would add? Post a comment and let us know.

Also, If you’re a supply chain or logistics practitioner from a manufacturing, retail, or distribution company, I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-5 minutes per week) — plus your participation will help support charitable causes like JDRF, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.

You can also follow us on LinkedIn to stay informed of our latest research results and news.